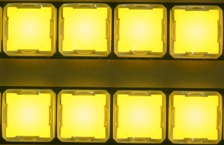

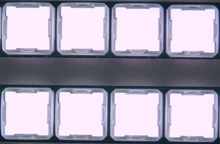

Multi-color LED represents any image in a wide variety of colors.

KA series Multi-color LED image

Multi-color LED is possible to emission of 256 colors.

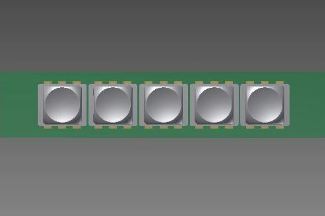

Smart, Unifiled Design and Variously button size

Stable, consistent color and brightness

KA, K2, K9 Red, Super green, dual-color(Yellow)

KA Multicolored White and Blue

More than 50% reduction of mounting cost comparing to DIP type.

Surface-Mountable Terminals (SMT) switch can be mounted directly by mounting machine

as same as other surface-mounted component.

SMT switches can be precisely mounted,

so it's unnecessary to correct or repair

of slanting and twisting.

Additionally,

It has not protrusive terminals on the reverse side of printed-circuit board,

it's unnecessary cutting work of the terminals.

It can achieve significant mount working time reduction from traditional manual fabrication.

| SMT switch |

DIP switch |

| Mounted 31 pcs by mounting

machine |

11 sec/pc |

Masking |

13 sec/pc |

| Alignment |

10 sec/pc |

| solder bath in flow soldering |

4 sec/pc |

| Peal off a heat-resistant sticker from the switch block and assemble the lighting block . |

7 sec/pc |

Retouch for slanting and twisting parts. |

11 sec/pc |

| |

18 sec/pc |

|

38 sec/pc |

Working time of mounting operation per- SMT switch (18sc/pc) can reduce more than 50%

from DIP switch (38 sec/pc). ※The data form the calculations of our own.

*No need of modification by hand working after SMT.

*Most suitable for overseas production because of automated way.

Not only cost but also quality will be improved by SMT.

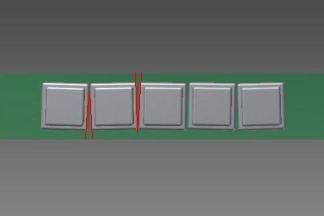

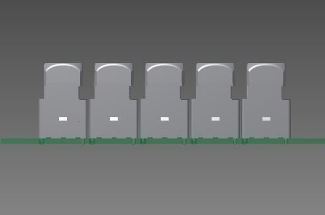

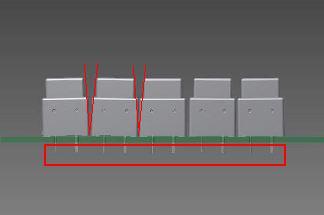

Sunmulon SMT switch Usual DIP switch

DIP switch often need to correct or repair of slanting and twisting, cutting work of the terminals after mounted.

Please see the surface-mounting process movie.

Surface-mounting Image ≫≫【Please see the movie for more details】

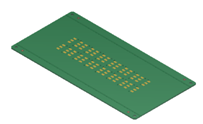

①Print the solder paste on the printed circuit board.

②Up to 96 units of switch block are put in the dedicated tray.

If ordered 32 units or more,

the order will be delivered in

a tray.

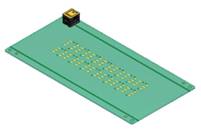

③Mount the switch block to the printed circuit board from tray by mounting machine.

④Dissolve the solder paste with the reflow soldering machine

and finished soldering.

Slanting and twisting during

mounting does not occur by our own know-how.

You can align switches in a straight line

without particular modifications.

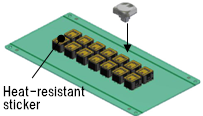

⑤Peel off a heat-resistant sticker from switch block,

and then assemble with the lighting block.

Easy to assemble by modular switch concept, composed of

switch

block and lighting block.

⑥Surface-mounting finished.

Stable active position,Long operating life,Smooth operating feeling.

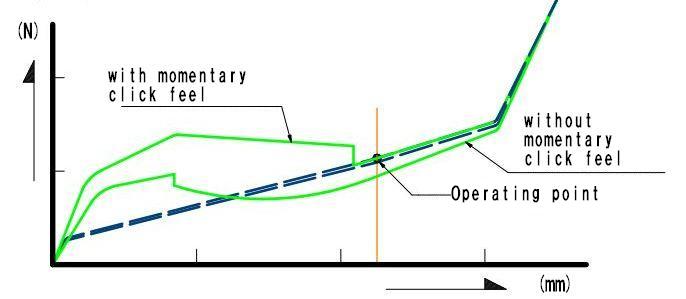

【KA, K2 Series switch operationg characteristic curve】Total travel 3.5mm(MAX 4.0mm)

KA, K2 Electrical life More than 3,000,000 operations

*Two types of switching action - with or without audible click.

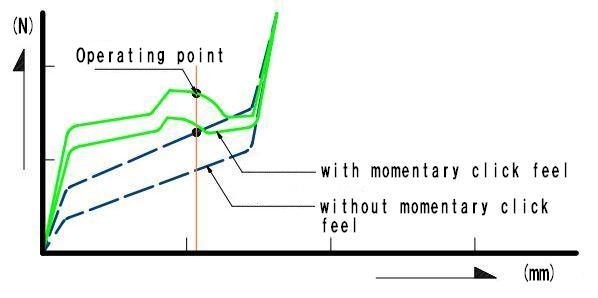

【K9 Series switch operating characteristic curve】Total travel 1.5mm(MAX 2.0mm)

K9 Electrical life More than 300,000 operations

*Two types of switching action - with or without audible click.

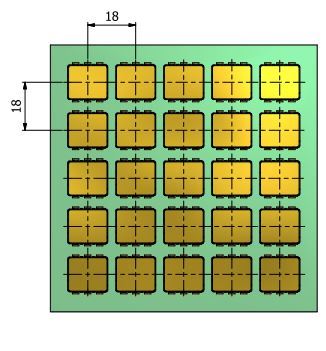

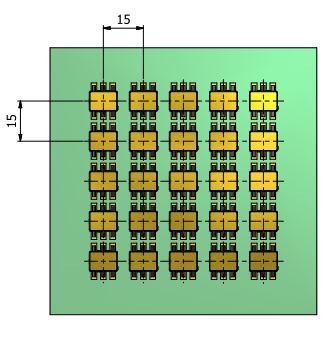

Minimum pitch in case of continuous and high density mounting.

KA Minimum pitch 18mm K2, K9 Minimum pitch 15mm

For more information, please refer to the above PDF DATA.

PDF DATA SMT series KA,K2,K9 (AVAILABLE FROM HERE).

|